Numerical Formulation

In order to support novel oxy-combustor designs, a high-fidelity yet numerically efficient modeling framework based on the CRUNCH CFD flow solver was developed, featuring key physics-based sub-models relevant in this regime. For computational efficiency in modeling large kinetic sets, a flamelet/progress variable (FPV) based tabulated chemistry approach is utilized featuring a three stream extension to allow for the simulation of the CO2 film cooling stream in addition to the fuel and oxidizer streams. Finite-rate chemistry effects are modeled in terms of multiple progress variables for the primary flame as well as for slower-evolving chemical species such as NOx and SOx contaminants. Real fluid effects are modeled using advanced equations of states. The predictive capabilities of this computationally-tractable design support tool are demonstrated on a conceptual injector design for an oxy-combustor operating near 30 MPa.

Results

Simulations results provide quantitative feedback on the effectiveness of the film cooling as well as the level of contaminants (CO, NO, and N) in the exhaust due to impurities entering from the injectors. These results indicate that this framework would be a useful tool for refining and optimizing the oxy-combustor designs as well as risk mitigation analyses.

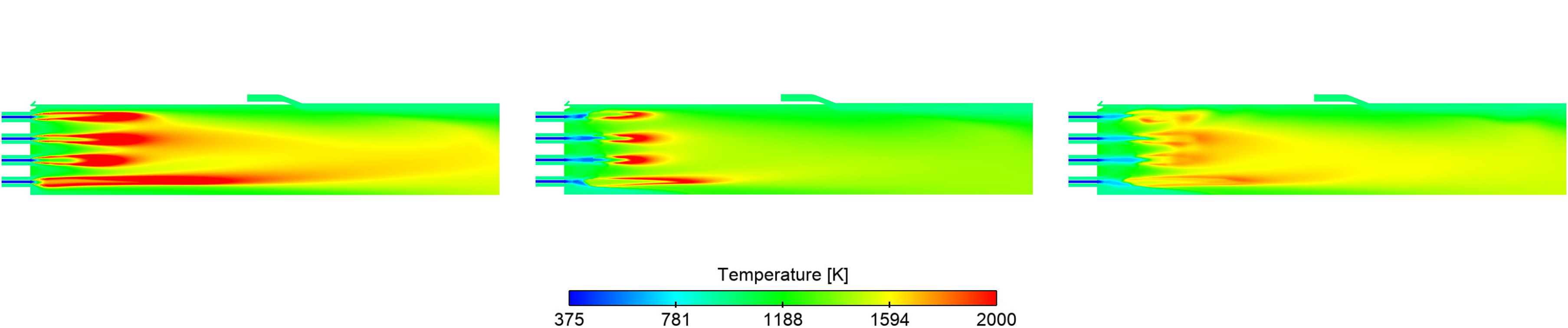

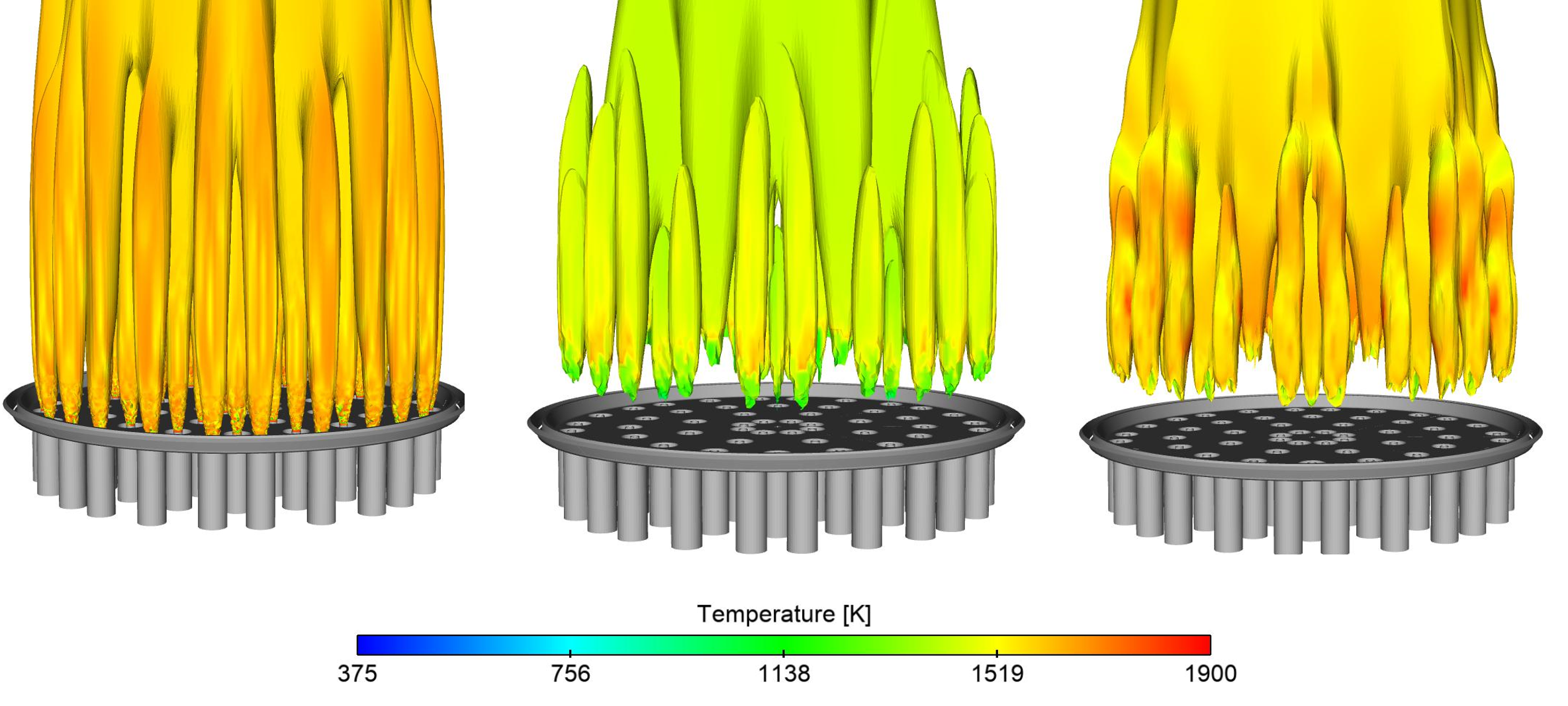

Case 1: Flamelet Mixing Controlled

Attached flames, mixing controlled combustion

Case 2: Flamelet Progress Variable

Lifted flames and overall lower flame temperatures due to finite rate chemistry effects

Case 3: Turbulent Flamelet Progress Variable

Lower flame temperature and more disperse flame with increased temperature surrounding flame due to turbulent mixing

Zambon, A. C., Hosangadi, A., Weathers, T., Winquist, M., Mays, J., Miyata, S., and Subbaraman, G. (January 4, 2021). "A High-Fidelity Modeling Tool to Support the Design of Oxy-Combustors for Direct-Fired Supercritical CO2 Cycles." ASME. J. Eng. Gas Turbines Power. January 2021; 143(1): 011016. https://doi.org/10.1115/1.4049350